Safe locks play a crucial part in security systems such as fire and gun safes, bank vault doors, security containers and safe storage applications. The security level of the safe locks to a large extent equals the security performance of the entire safe.

What’s more, it’s the locks that end-users are directly dealing with in everyday life, so it’s essential to choose an ideal safe lock that best suits your needs.

In this article, you will learn:

- What Is a Safe Lock

- How Does a Safe Lock Work

- How to Use a Safe Lock

- Mechanical Safe Lock

- Electronic Safe Lock

- Key Lock

- Safe Deposit Lock

- How to Change a Safe Lock

What Is a Safe Lock

A safe lock is a type of high-security lock specially designed and primarily used on safes that works in conjunction with a boltwork. Due to their high-security performances, safe locks are commonly used as the main locking system on other safe storage products as well, such as vault doors, ATMs, and security containers.

How Does a Safe Lock Work

Unlike regular locks, the safe locks are located and installed behind the safe’s door, making them difficult to attack, drill out, or destroy. The dials of mechanical locks and the keypads of electronic locks on the surface of the door are only an entry unit to input the combination and codes to the safe lock inside.

All combinations and codes are securely stored in the safe lock behind the door, so the door will remain locked even if you remove or destroy the lock parts outside the safe or change the keypad with the one you know the correct code of.

Another significant characteristic about safe locks is that most safe locks do not directly control the locking and closing of the doors. Usually, the safe handles, safe locks, and the safe’s locking bolts are connected via boltwork.

When the safe lock is locked, the lock bolt is extended and blocks the boltwork from movement. The safe handle cannot rotate to retract the door’s locking bolt in order to open the door.

When the safe lock is opened with a valid code, the lock bolt retracts and releases the boltwork. Now the boltwork is able to move and you can use the handle to rotate the boltwork, retracting the safe’s locking bolts and open the safe’s door.

The benefit of the working mechanism using a boltwork is that even if the safe lock inside the door is drilled out or destroyed by force, there are still methods to keep the door locked as the locks do not control the door’s locking bolt directly.

One of the common methods is to add a relocker on the boltwork. When the lock is drilled out or tampered, the relocker will trigger, lockout the boltwork, and prevent it from moving. So even if the lock is completely removed, the safe still remains securely closed. To open the safe, you need to call a locksmith or a safe technician to drill out all the relockers to technically get it open.

In cheap and basic safes, it’s common to use the locks as the locking bolts, similar to a regular door lock. When the locks are drilled out or damaged, the safe instantly opens. This kind of safe is more like a metal lock box and is clearly less secure.

How to Use a Safe Lock

Generally, operating a safe lock is not much different from using a regular lock. But there are some differences worth mentioning.

To open the safe, first you need to open the lock. Dial the combination or enter the passwords if they are mechanical or electronic combination safe locks, or insert the key to open the key lock. When the lock is opened and the lock bolt retracts, turn the safe’s handle to fully retract the locking bolts to its open position, then pull the door open. This step is similar to opening regular door locks.

To close the safe, push the door back to its door frame and turn the handle the other way to fully extend the locking bolts. Unlike home door locks, most safe locks do not automatically lock themselves, meaning the lock is still in the open position, and the lock bolt is still retracted after you close the door. You need to lock the safe lock as well, so the lock bolt extends to block the boltwork after you shut the door, especially for mechanical locks.

This is also one reason why you cannot withdraw the key when the key lock is opened. The inserted key on the door’s surface reminds you that the lock is still open, and you need to withdraw the key to completely close the door.

For mechanical dial safe locks, the correct combination you just dialed is still inside the lock even after it’s locked and bolt extended. You can instantly open the lock by turning the dial without dialing the combination. It’s important to remember to spin the dial randomly multiple revolutions to use a random combination to cover the correct one completely.

Though most electronic safe locks can automatically lock and extend the lock bolt after several seconds when opened, there are still some digital locks that require you to close them manually, such as the electronic lock with a rotary keypad. It’s always a good thing to double-check and ensure the safe is securely closed until you are one hundred percent sure how your safe lock works.

Mechanical Safe Lock

A mechanical safe lock is a kind of combination lock that consists of a dial & ring and a deadbolt combination safe lock. There are 3 or 4 wheel packs, each equally divided and representing the number from 1 to 100 in the combination that makes up the entire code.

For example, a 3-wheel safe lock has three wheels inside the lock with a possible combination variations of one million(100*100*100=1,000,000).

A 4-wheel safe lock has four wheels inside the lock with one hundred million theoretical combinations(100^4=100,000,000).

The dial and ring set is for users to input their code into the safe lock via a spindle by spinning the dial left and right to the desired numbers. Since people do not see the lock behind the safe and only see and operate the dial most of the time, a mechanical safe lock is often called a mechanical dial lock or safe dial lock as well.

How Does a Mechanical Safe Lock Work

The mechanical safe combination lock mechanism is relatively simple and has remained unchanged over centuries. The benefit of a simple but clever design is that the simpler the mechanism is, the fewer chances the lock might error or fail, which is great for the lock’s stability and dependability. The design of the dial locks is very common and nearly all safe lock manufacturers share the identical design and add their own improvements and variations over it.

In this guide, we are not going to explain the mechanism in details but to simplify it so every reader would instantly know how a safe dial lock works without learning much lock industry-related knowledge.

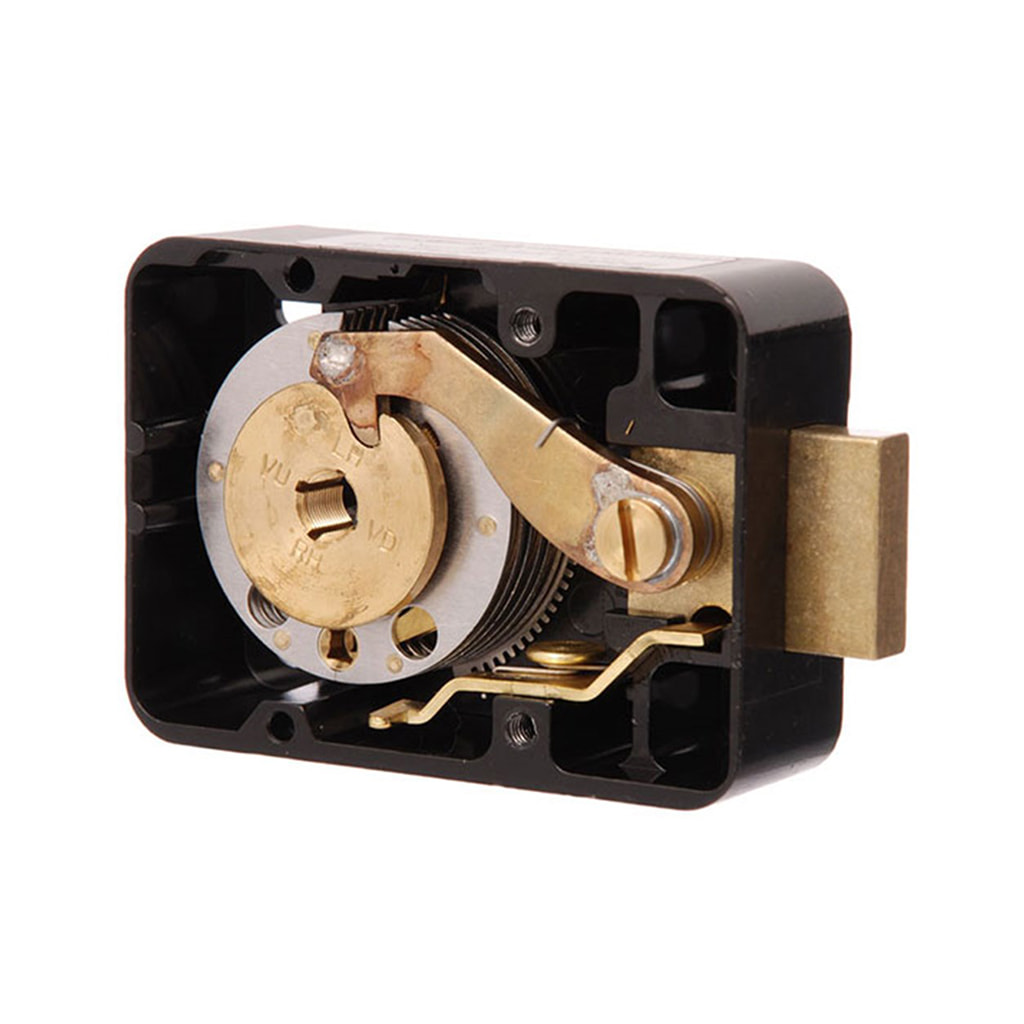

This is what a typical Sargent and Greenleaf, also known as S&G in the industry, 6700 series mechanical lock looks like inside. The S&G 6700 lock is one of the most widely used lock series, it is a “standard” mechanical safe lock, and we can use it as a universal example for explanation.

To open the lock, what we want to do is to align all the gates in the same line under the lever so the lever’s fence can fall into the gates to open the lock. Each wheel(sometimes called a disk) is equally divided into 100 positions which represents the code number 1 to 100. To dial all the correct combinations is the process to align all the gates under the fence.

Here is a simplified animation showing how each wheel is turned sequentially. Note that first we need all the wheels to move together so this is why we need to turn the dial CW or CCW multiple times before we enter the combination.

When each correct combination number is entered, we need to spin the dial the opposite way to not continuously move that wheel. This is why we need to turn the spin left and right while inputting the code. And this is also why If you accidentally pass any of the correct numbers, you cannot turn back the dial and should start all over from the beginning.

Whether it’s a 3-wheel or 4-wheel lock, it’s always to turn the dial clockwise finally to open the lock and retract the bolt. So there is a difference on which way to first turn the dial because the wheel numbers are different. And it’s also different on how many times you need to keep spinning the dial before dialing the combination to move all the disks.

Dial Open a 3-Wheel Mechanical Safe Lock

Suppose you have a three digit combination such as 11-22-33

- Turn the dial to the left(CCW), stop when your first number(11) comes under the opening mark the 4th time.

- Turn the dial to the right(CW), stop when your second number(22) comes under the opening mark the 3rd time.

- Turn the dial to the left(CCW), stop when your third number(33) comes under the opening mark the 2nd time.

- Turn the dial slowly to the right until it stops to unlock and retract the bolt.

- To securely relock the lock, turn the dial to the left at least 4 revolutions to clear all the combinations you entered.

Dial Open a 4-Wheel Mechanical Safe Lock

Suppose you have a four digit combination such as 11-22-33-44

- Turn the dial to the right(CW), stop when your first number(11) comes under the opening mark the 5th time.

- Turn the dial to the left(CCW), stop when your second number(22) comes under the opening mark the 4th time.

- Turn the dial to the right(CW), stop when your third number(33) comes under the opening mark the 3rd time.

- Turn the dial to the left(CCW), stop when your fourth number(44) comes under the opening mark the 2nd time.

- Turn the dial slowly to the right until it stops to unlock and retract the bolt.

- To securely relock the lock, turn the dial to the left at least 5 revolutions to clear all the combinations you entered.

Change the Combination of a Mechanical Safe Lock

The combination of the lock is determined by the wheels, so to change the combination of a mechanical safe lock is to make changes to the inner relative position of the wheels.

It’s very important to always leave the door open while changing the combination.

To change the combination, users should first successfully open the lock, so all the wheels are already in the open position with the lever’s fence falling in all gates in all the wheels. By inserting and rotating a small tool called change key in the back of the lock, the three-layered wheel unlocks from the fixed status and becomes movable, allowing users to spin the inner part of the wheel to set the new combination. During the process of changing the combination, the fence and gates are always stuck together, so the new combination should also be able to open the lock.

After the new combination is set by spinning the dial, similar to how you dial the combination, remove the change key and the wheels become fixed again.

Now the new combination is successfully set, test the new code at least 3 times before closing the door.

Common Features

Key Locking Dial

A key locking dial contains a key cylinder lock that can prevent the dial from rotation which can add extra security protection against manipulation.

Spy Proof Dial & Ring

A spy-proof dial & ring can prevent unauthorized observation while dialing the combination. A spy-proof dial is also known as a top reading dial. The standard dial & ring without spy proof feature is called a front reading or open reading dial & ring.

Internal Relocker

A relocker is a component inside the lock case that can prevent the bolt from retracting when the lock cover is separated or removed to protect against forced entry and punch attacks. The relocker can be triggered by heat as well to protect against thermal attacks.

Mounting Position

The lock can be mounted four ways: right hand, left hand, vertical up, vertical down, also known as RH, LH, VU, VD.

- Right hand – bolt points right

- Left hand – bolt points left

- Vertical up – bolt points up

- Vertical down – bolt points down

Certification

The mechanical safe locks are classified by UL 768, which covers the requirement of combination locks intended for attachment on doors of safes, chests, vaults to provide a means of locking the boltwork against unauthorized opening.

According to UL 768, combination locks are classified as Group 1, Group 1R, Group 2M, or Group 2.

- GROUP 1: Those locks that have a high degree of resistance to expert or professional manipulation. The protection against professional manipulation includes advanced design features not found in conventional designs. Group 1 locks also have 20 working hours of resistance to expert or professional manipulation.

- GROUP 1R: Those locks shall have 20 working hours of resistance to expert or professional manipulation the same as for Group 1. And, in addition, have 20 working hours of resistance to radiological attack such as X-ray imaging.

- GROUP 2M: Those locks that have 2 working hours of resistance to expert or professional manipulation.

- GROUP 2: Those locks that have a moderate degree of resistance to unauthorized opening.

Dialing Tolerance

The dialing tolerance means the lock shall not open when the dial is more than certain graduations on either side of the proper graduation for each wheel.

For example, if the correct code is 11-22-33 and the lock has 1 tolerance, you can open the lock with either combination from (11±1)-(22±1)-(33±1) range. The smaller the tolerance, the safer the lock is.

- GROUP 1, GROUP 1R

- 3-wheel: Tolerance 1

- 4-wheel: Tolerance 1.25

- GROUP 2M, Group 2

- 3-wheel: Tolerance 1.25

- 4-wheel: Tolerance 1.5

Electronic Safe Lock

An electronic safe lock consists of a keypad as the entry unit to input codes and signals and the electronic safe lock that blocks the boltwork. An electronic safe lock is easy to use, quick to open, and it has many useful features that make it the optimal safe lock choice for most safes, especially gun safes that require quick access and commercial safes that require a certain level of user management.

How Does an Electronic Safe Lock Work

Upon the entry of a valid code, the electronic safe lock unlocks and allows the boltwork to move freely in order to open the safe. Unlike mechanical locks where users can only manually retract the bolt by rotating the dial, digital safe locks offer more ways to interact with the boltwork.

Currently, there are several types of lock bolts available that each act differently on how they block and release the boltwork.

Swing Bolt

Swing bolt, also known as Pivot Bolt or RotoBolt by other brands, is the most popular bolt type on electronic safe locks. When in the locked position, the swing bolt is fixed and unmovable, blocking the safe’s boltwork from rotation.

When the electronic lock body is unlocked with a valid code, the bolt becomes moveable, allowing the boltwork to rotate the bolt into the lock body to open the safe’s door. The lock will remain unlocked for about 6 seconds and then relocks automatically. Once the safe’s door is closed and the boltwork is fully closed, the lock is now fully relocked and the swing bolt fully extends and becomes immovable that blocks the boltwork from opening the safe.

One reason why swing bolt lock is the most standard and widely used electronic safe lock is that the swing bolt’s retraction and extension is completely controlled by the safe’s boltwork. Mechanical dial or key safe locks require users to manually retract and extend the bolt by rotating the dial or the key, so after the users close the door and rotate the safe handle to its closed position, they still need to manually relock the lock to extend the lock’s bolt. It’s an extra step compared to swing bolt locks and it’s high chances that people would forget to lock the safe lock, leaving the safe wide open.

But with swing bolt lock, we don’t have to worry about relocking again. As long as we close the door and rotate the safe handle to the locked position, the swing bolt is already extended and automatically relocked.

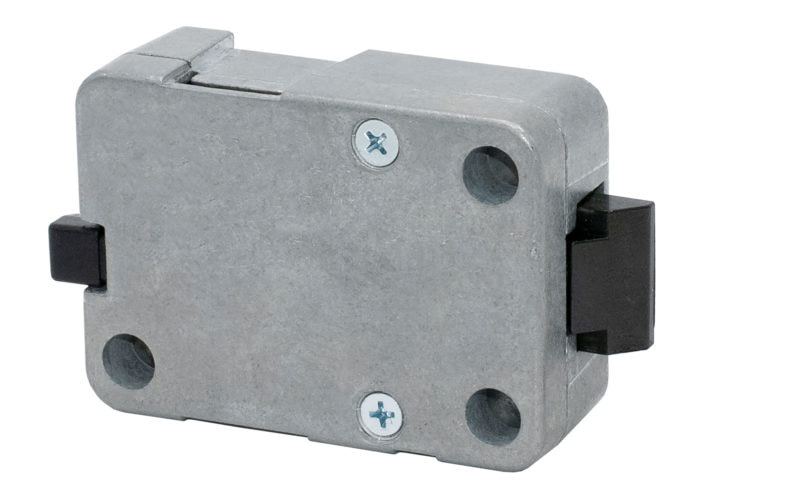

Dead Bolt

Dead bolt, also known as Square Bolt safe lock is another primary bolt type used on electronic safe locks. Similarly, the deadbolt safe lock blocks the boltwork by retracting and extending the bolt. One advantage of dead bolt safe lock is that the square bolt can have pre-drilled and tapped holes for direct bolt work attachment.

Currently, there are three types of deadbolt locks on the market:

- Direct Drive Dead Bolt: The lock bolt is retracted and extended by manually turning the keypad. The keypad and the lock are connected via a spindle similar to mechanical dial locks. When the lock is entered with a valid code, users can turn the keypad to manually retract and extend the bolt. The direct drive dead bolt is also available for direct boltwork attachment.

- Auto Relocking Dead Bolt: The lock bolt is retracted and extended by a motor and spring inside the lock case. When a valid code is entered, the motor retracts the bolt for about 6 seconds. After 6 seconds, the spring extension inside the lock pushes the bolt back to the locked position, so the lock can automatically relock when the user closes the door, and the boltwork fully extended.

- Push Pull Dead Bolt: The lock bolt is retracted and extended by a motor inside the case. Additionally, the push-pull lock has a strength of about 2 pounds to pull and push the lock bolt. This lock has pre-drilled and tapped holes for direct boltwork or lock attachment.

Spring Bolt

Spring bolt, also known as Latch Bolt, is designed for applications where a boltwork system is not provided, such as the inner compartments of the safe or high-security cabinets. The non-dead latching bolt is motor-driven and the bolt is retracted by the motor and relocks via spring extension. The spring bolt electronic lock directly controls the door just like regular latch bolt door locks, so no handle or boltwork is required.

Solenoid and Motor-Driven Lock

Inside the electronic lock, there are two mechanisms used to control the lock bolt: solenoid lock and motor.

Solenoid lock, or solenoid blocking, was the standard way and used in the early days of electronic safe locks. When the correct code is entered, the solenoid lock retracts, allowing the swing bolt to retract or deadbolt to move. But solenoid lock based electronic lock is weak against punch attacks and magnetic attacks, which makes the safe easily get opened without a valid code. Though lock manufacturers have increased the security performance on solenoid safe locks with upgraded designs against such attacks, in recent years, most manufacturers discontinued using the solenoid lock as the bolt blocking system, and they use motors instead.

The motor-driven lock is the new industry standard in electronic safe locks. The lock bolt is driven or controlled by the motor, which makes the electronic safe lock immune to punch and magnetic attacks. The motor can be used to block the lock bolt in swing bolt lock or used to retract and extend the lock bolt in auto-relocking dead bolt locks. Motor-driven safe lock is more secure and you should choose motor-driven safe locks, especially on your high-end safes.

Types of Electronic Safe Lock

You might have seen multiple types of electronic safe locks used on safes that look completely different. Currently there are three types of electronic safe locks.

Basic Safe Lock

The basic electronic safe locks do not have a swing bolt or dead bolt lock body that works in conjunction with a boltwork. They are usually simple designed and use the solenoid lock inside to block the safe’s boltwork from moving. Basic safe locks are designed to be used on small safes with a basic level of security protection, such as hotel and lightweight fire safes. Usually, these locks would integrate the locking bolts into the lock case so the locks can be installed directly on the safes without the need for extra mechanisms for the safe to work. Basic digital safe locks would usually include a key lock as the backup opening method in case the digital lock does not work.

Standard Safe Lock

Standard electronic safe locks consist of a keypad as the input unit and a swing bolt or dead bolt lock body to block the boltwork from moving. The keypad is often round shape and the locks might have useful features such as user and manager code, time delay, and dual-mode. Standard electronic safe locks are the most common digital safe locks used in most gun safes, home safes and fire safes.

High-Security Safe Lock

Upon the request of the maximum level of protection on valuables, high security electronic safe locks have been introduced to solve such problems. These high-security electronic safe locks usually have a larger, square input unit as the mechanism is much more sophisticated. And they can be online connected and controlled via softwares or work offline as a standalone safe lock device. One example is the Dormakaba Paxos lock that has all components in the secured area doubled, which is nearly impossible to fail during regular operations.

How Secure Are Electronic Safe Lock

One of the major concerns about electronic safe locks is how secure they are, what if they fail or the battery dies.

Well, modern electronic safe locks are very reliable and they rarely fail. Even though all electronic components may eventually fail, your valuables inside the safe are properly stored and secured, so do not worry.

What Happens When the Electronic Safe Lock Fails

When the electronic safe lock fails, gets damaged or even pried off of the safe, the safe is still securely locked because the lock’s bolt is still extended, blocking the boltwork from retracting the locking bolts. The keypad on the surface of the safe is only an entry unit and the main safe lock is safely located inside the safe. Even when the electronics in the safe lock body fail, the bolt is still in the locked position.

How to Get Into the Safe When the Electronic Safe Lock Fails

Well, you cannot get into the safe when the electronic safe lock fails, get damaged or even removed because that’s the purpose of secure locking. You should call a safe technician or locksmith to technically get the safe open.

If you have a redundant lock or a secondary override lock system as the backup access, you can use the mechanical redundant lock or the secondary key lock to open the safe, bypassing the failed electronic safe lock.

How to Get Into the Safe if the Battery Died

Most electronic safe locks have the batteries installed inside the keypad, so users can easily change the batteries from outside the safe even if the batteries die. The code is stored in non-volatile memory inside the safe lock and can last for a long time without batteries, so you don’t have to worry about the password getting lost.

For some electronic locks that have the batteries located inside the safe, there is usually an external power supply method on the keypad, such as a USB port, to temporarily supply power to the safe lock.

Common Features

User Management

Electronic safe locks allow multiple levels of user management, such as user code, manager code, master code and supervisor code. Each level of user is capable of certain actions, such as disabling or adding lower-level user codes, changing working mode, and more complicated functions.

Access Methods

There are multiple ways to access the lock, such as single user mode and dual user mode.

Single user mode is the standard mode that only one user code is required to open the lock.

Dual user mode, commonly known as the dual mode, requires two individual users to open the lock simultaneously. It requires two different valid codes to be entered within one minute of each other for the lock to open so that no one person has the ability to open the safe alone. Dual-mode safe locks are widely seen and installed on ATMs.

Time Delay

If the time delay feature is enabled, after the valid code is entered, the safe lock still cannot open until the time delay period expires. Time delay forces a 00-99 minute waiting time between the entry of a valid code and the opening of the safe. Time delay safe locks are usually used on retail store safes, cash carrier or armored car pickup process. The time delay feature is to deter armed robbery because when the manager is forced to open the safe, he can still enter the correct code but the safe will not open. There is no way but to wait for the time delay to expire.

Statistics have found that the longer it takes to open the safe, the less likely the crime will continue. Most of the time, it is recommended or even requested to add a “Time Delay Enabled” label on the safe to let the burglars know they have to wait for the safe to open to decrease the possibility of a crime from happening.

There is also a time delay override code, or TDO code, to bypass the time delay and instantly get the safe open. When there is no crime, it is unnecessary to wait for the safe to open. The quicker we open the safe and transfer the cash inside, the more secure and efficient it is.

Duress Mode

Duress mode is also known as silent alarm. When the duress mode is enabled, users can open the lock like usual with the duress code. In the meantime, the lock will send a silent alarm to the security room indicating an unauthorized access or crime is happening. The duress code combination is usually one digit higher or lower to the last digit of the valid user code.

Wrong Try Penalty

To prevent code manipulation, if four invalid combinations are entered in a row, the lock will shut down for 5 to 15 minutes with continuous beeping to indicate the lock is on wrong try penalty mode, depending on various lock models.

During the lockout, you should not do anything to the keypad, try to enter the valid combination or try to disconnect the power to the keypad and restore. Each action may result in resetting the timer. Patiently wait for the wrong try penalty to expire and enter the valid combination to unlock.

Reset the Lock

Electronic safe locks offer reset methods to quickly restore the lock to factory default settings. Usually, these locks can be reset via reset codes, reset button on the lock case or other external reset methods.

Low Battery Signal

The lock will have a low battery warning to indicate the battery is low and needs to be replaced immediately. Usually there are beeping sound signals and visual signals depending on each lock model.

Change the Combination

Electronic safe locks allow users to change the combination in an easy way via the keypad. It’s also the first thing to do when you get your new safe from your supplier is to change the default factory code. Though different lock manufacturers have their own ways to change the combination, it’s critical to remember to always leave the door open while changing and test the newly set code at least three times before you close the door.

Audit Trails

Audit locks allow users to view the latest audit trails on the keypad with display or retrieve and download the audit events from the keypad to the computer.

Certification

In the United States, electronic safe locks are covered by UL 2058 which is the standard for high-security electronic Locks. UL 2058 only has one grade, so the electronic safe locks which are certified to meet the criteria of UL 2058 are listed as UL Type 1.

Key Lock

The mechanical key locks used on safes, security containers or safe storage products, also known as key operated safe locks, are mostly double-bitted lever key locks. The lever key locks used on safes should have at least 7 levers to provide sufficient key variations. There are also wheel technology combination key locks available on the market that are similar to dial safe locks controlled by a special key instead of the dial, such as the LaGard 2270 key lock.

Key locks are usually used as the secondary lock on dual lock high-end safes or as the backup lock to open the safe when the main electronic lock fails. Single key lock operated safes are not widely seen in the U.S market but are very popular in the European region.

Common Features

Right Hand and Left Hand Lock

Usually, the key locks are all right-handed(R.H. or RH) locks, but left-handed(L.H. or LH) locks are also available upon request.

Key Changeable

For regular lever key locks, if you want to rekey the lock, you need to disassemble the lock and reorganize the levers to make the lock adapt to new keys.

Key changeable locks allow users to disable old keys and set new keys without disassembling the lock, usually via a change key or a change button on the back of the lock case. In case of a lost or duplicated key, you change the key only without the need to replace the entire lock.

Keys Retaining

The key retaining feature forces the key retained in the lock and cannot be withdrawn when the key lock is in the open position. It’s a security feature that ensures the safe is always securely locked when the key is removed from the lock.

The retained key in the lock is also a reminder that your safe is still open even when you close the safe door, and it can also prevent you from accidentally having the keys locked in the safe.

Non Key Retaining

The non key retaining feature allows the keys to be removed from the lock when the key lock is in open position. The non key retaining key lock is usually used on dual lock safes with a combination lock and a key lock, so you can leave the key lock always open and only use the combination lock to open the lock when needed.

Master key System

Key locks with a master key system allow the lock to be opened either by its individual user key or the superior master key. Master key locks are usually used in a group of security containers for easy management, such as compartments, lockers and gun cabinets. Each user key can only open its own lock and the master keys can open all the locks in the same hierarchy of the lock group.

Detachable key

The detachable key consists of a key stem and a detachable key bit. It’s easier to store and carry only the small part of the key b:it without the necessity to hold the entire key, especially when the key is very long.

Folding Key

A folding key is a design to solve the problem where the keys are very long, so the key stem can be folded in half to shorten the total length.

Certification

In the US, the UL 437 is the standard and certification for safety key locks, which covers the security container key locks and two-key locks. The security container key locks are identical to safe key locks, and the two-key locks are identical to safe deposit locks.

Under UL 437, the security container key locks shall have at least one million key changes for a design and the key of a security container key lock shall be field changeable.

The UL Type 2 security container key lock shall have at least 30 minutes attack resistance working time against attacks including: picking, lock bumping, impression, forcing, drilling, sawing, prying, pulling and driving.

The UL Type 1 security container key lock shall have at least 20 hours attack resistance working time against attacks including: picking, lock bumping and impression, and 60 minutes attack resistance working time against attacks including: forcing, drilling, sawing, prying, pulling and driving.

Safe Deposit Lock

Safe deposit locks are single bitted lever locks with two keys inside the lock case. These two-key locks are mostly installed on bank safe deposit boxes that require both the key from the renter and the key from the bank to open the lock at the same time, so they are often called safe deposit locks most of the time.

Certification

The safe deposit lock is also certified by UL 437, the same as the key locks. UL 437 only has one grade for safe deposit lock for those which meet the criteria of the two-key lock tests.

Under UL 437, there shall be at least 64 guard key changes, and at least 15,000 customer key changes for a design.

How to Change a Safe Lock

When the lock fails, gets damaged or needs an upgrade, the existing safe lock needs to be replaced with a new one. It’s also a common request by the safe owners to install a dial lock on a safe replacing an electronic lock, or change the electronic safe lock to mechanical.

Changing a safe lock is not hard, DIYers can replace the lock following the lock’s instruction manual most of the time without an effort. For some sophisticated electronic safe locks or safes, you can call a locksmith for the lock replacement.

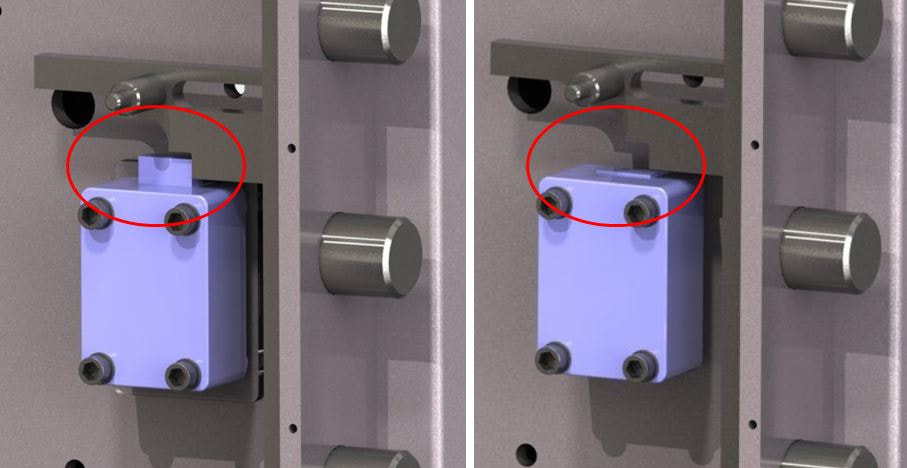

The majority of safe locks share the same standard footprint and follow the same mounting dimension 66 mm x 41 mm, so they can interchange and replace each other freely without extra modification. For example, when purchasing a safe, most safe manufacturers would offer lock options so that customers can choose to install a mechanical dial safe lock or electronic safe lock on their safes. Safe manufacturers use a universal installation dimension so they can install either a mechanical or electronic lock on the same safe model.

Before changing the safe lock, first make sure the dial and the keypad have the same mounting dimension. Though most manufacturers use the same industry standard dimension for the entry unit as well, there are various lock models that have their special designs and may not be compatible with others.

It’s relatively easy when you change the mechanical lock to an electronic safe lock. The wire goes through the hole for the spindle, connecting the keypad and the safe lock, that’s all.

For high end electronic safe locks, you may have some difficulty in installation, but it’s all doable, following the instruction manual and it does not require hard modification to the safe’s mechanism.

When you need to change the electronic safe lock to a mechanical lock, you need first to make sure whether your safe is available for such replacement. Electronic safe locks are connected by a wire, so the safe lock does not necessarily located right behind the keypad due to the safe’s boltwork and inner mechanism.

Unscrew and open your safe’s door and check the boltwork inside. If the electronic lock is located right behind the keypad and the hole for the wire is big enough for the spindle, then you can replace it with a mechanical lock quickly without modifying the safe. If the electronic lock is not located right behind the keypad, you need to ask a safe technician to drill some holes for a proper replacement or alter the boltwork, which is a lot of work and not recommended.